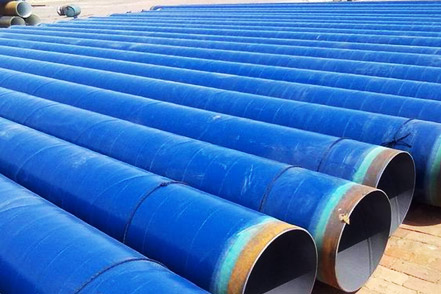

Dedicated Epoxy Dual-resistant Anticorrosive Powder Coating for Coal Mine Wells

Hotline:0536-8673066

- Details

Product Description:

This product phenolic resin, and added self-developed conductive polymers and conductive materials, conductive and intrinsically conductive doped in one of the advantages of the collection, is designed for heavy-duty powder coating conductive design, coating the surface resistance value up to 105 or less, and can effectively eliminate static electricity build-up of gas drainage pipes, to avoid static electricity sparks, improve safety performance. High reactivity, has a strong adhesion, high crosslink density coating with excellent chemical resistance, solvent resistance, cathodic peeling resistance, excellent flexibility, impact resistance and other properties.

Product Features:

1, the substrate has a very good adhesion.

2, the first application of independent research materials, set intrinsically conductive doped conductive in one.

3, the conductive coating film is good, the coating film surface resistance of up to 105, the effective elimination of the surface charge accumulation

4, coating and metal interface form an anti-electric field, shielding electron transfer, to protect the metal.

5, the coating has excellent high temperature resistance to cathodic stripping ability.

6, low melting temperature, high reactivity, curing completion rate, good mechanical properties.

7, adding composite flame retardant, flame retardant has a certain effect.

Application areas: coal mine gas ventilation, drainage pipes special anti-static anti-corrosion coating.

Executive Standard: MT 181-88

Construction Description:

1, coating method: a, high-voltage electrostatic spraying / priming coat b, fluidized bed dipping c, Pit dip

2, the proposed film thickness: 300 ---- 400um (depending on the substrate diameter)

3. Surface treatment: acid phosphate or sand blasting, shot blasting, anchor pattern depth 50--80um.

4, the workpiece preheating: tunnel furnace heating, front steel surface dusting reach 130 --- 180 °, not less than 130 °

5, the curing temperature: tunnel furnace heating, heating pipe surface reaches 180 ° / 15min, 200 ° / 10min

6, test packaging: steel surface quality can check and repair the leak at 80 ° or less.

Health and Safety:

The powder coating does not contain toxic substances, baking and no toxic gases. But in the course of inhalation of dust should be avoided, the operator should wear dust masks, glasses, protective clothing and other protective equipment, and to minimize prolonged contact with the skin, attached to dust the skin, wash with soap.

Disclaimer:

This technical information is only for reference, specific indicators are detected in income under certain conditions, represent the characteristics of the product. When customers use, subject to the actual case.

This product phenolic resin, and added self-developed conductive polymers and conductive materials, conductive and intrinsically conductive doped in one of the advantages of the collection, is designed for heavy-duty powder coating conductive design, coating the surface resistance value up to 105 or less, and can effectively eliminate static electricity build-up of gas drainage pipes, to avoid static electricity sparks, improve safety performance. High reactivity, has a strong adhesion, high crosslink density coating with excellent chemical resistance, solvent resistance, cathodic peeling resistance, excellent flexibility, impact resistance and other properties.

Product Features:

1, the substrate has a very good adhesion.

2, the first application of independent research materials, set intrinsically conductive doped conductive in one.

3, the conductive coating film is good, the coating film surface resistance of up to 105, the effective elimination of the surface charge accumulation

4, coating and metal interface form an anti-electric field, shielding electron transfer, to protect the metal.

5, the coating has excellent high temperature resistance to cathodic stripping ability.

6, low melting temperature, high reactivity, curing completion rate, good mechanical properties.

7, adding composite flame retardant, flame retardant has a certain effect.

Application areas: coal mine gas ventilation, drainage pipes special anti-static anti-corrosion coating.

Executive Standard: MT 181-88

Construction Description:

1, coating method: a, high-voltage electrostatic spraying / priming coat b, fluidized bed dipping c, Pit dip

2, the proposed film thickness: 300 ---- 400um (depending on the substrate diameter)

3. Surface treatment: acid phosphate or sand blasting, shot blasting, anchor pattern depth 50--80um.

4, the workpiece preheating: tunnel furnace heating, front steel surface dusting reach 130 --- 180 °, not less than 130 °

5, the curing temperature: tunnel furnace heating, heating pipe surface reaches 180 ° / 15min, 200 ° / 10min

6, test packaging: steel surface quality can check and repair the leak at 80 ° or less.

Health and Safety:

The powder coating does not contain toxic substances, baking and no toxic gases. But in the course of inhalation of dust should be avoided, the operator should wear dust masks, glasses, protective clothing and other protective equipment, and to minimize prolonged contact with the skin, attached to dust the skin, wash with soap.

Disclaimer:

This technical information is only for reference, specific indicators are detected in income under certain conditions, represent the characteristics of the product. When customers use, subject to the actual case.